Manual handling involves lifting, carrying, pushing, or pulling objects, posing risks of injury. Proper techniques and risk assessments are essential to ensure safety and reduce workplace hazards.

1.1 Definition of Manual Handling

Manual handling refers to the use of bodily force to lift, lower, push, pull, carry, or move loads. It involves physical actions that can pose risks of injury, particularly to the musculoskeletal system. The LITE framework helps assess these risks by focusing on Load, Individual, Task, and Environment, ensuring safer handling practices are implemented to reduce workplace injuries.

1.2 Importance of Manual Handling Safety

Manual handling safety is crucial as it prevents injuries, reduces workplace risks, and enhances overall well-being. Proper training and risk assessments, such as those guided by the LITE framework, help identify potential hazards and mitigate them, ensuring a safer environment for employees and improving operational efficiency by minimizing downtime due to accidents.

What is LITE in Manual Handling?

LITE is an acronym representing Load, Individual, Task, and Environment, used to assess risks in manual handling. It helps ensure safe practices by evaluating these key factors.

2.1 Breakdown of the LITE Acronym

LITE stands for Load, Individual, Task, and Environment. Each component helps assess risks in manual handling. Load refers to the weight and size of the object. Individual considers the person’s physical capabilities. Task involves the type of activity, like lifting or pushing. Environment examines the surrounding conditions, such as flooring and lighting. Together, they ensure a comprehensive safety evaluation.

2.2 Importance of LITE Assessment

The LITE assessment is crucial for identifying and mitigating risks in manual handling. It ensures tasks are evaluated systematically, considering the load, individual, task, and environment. This approach helps prevent injuries, improves safety, and reduces workplace accidents. By addressing each factor, LITE promotes a safer working environment and compliance with legal requirements, ultimately protecting both employees and employers from potential hazards.

Load in LITE

Load refers to the physical characteristics of the object being handled, including weight, size, shape, and stability. Evaluating load factors ensures safe handling and minimizes injury risks.

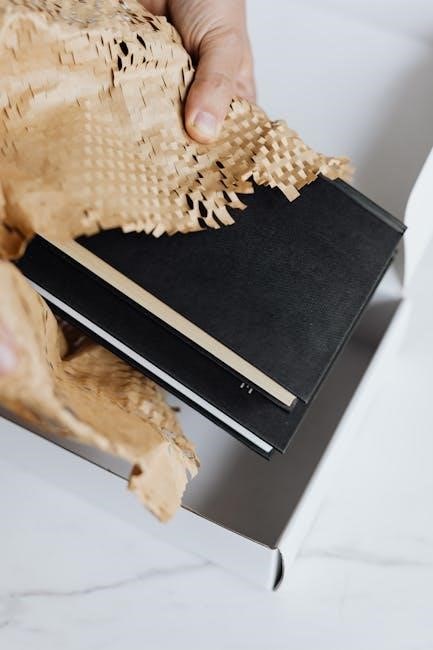

3.1 Factors to Consider for Load Handling

When assessing load handling, consider weight, size, shape, and stability. Uneven or unstable loads increase risk. Additionally, surface texture and temperature can affect grip and handling comfort. Proper evaluation ensures safe manual handling practices, reducing the likelihood of accidents and injuries. These factors are crucial for a thorough risk assessment in the workplace.

3.2 Assessing Load Characteristics

Assessing load characteristics involves evaluating weight, balance, and shape. Check for uneven distribution, stability, and surface texture. Consider how these factors affect grip and handling. Use tools or aids if necessary to stabilize the load. Proper assessment ensures safe handling techniques, minimizing risks of accidents and injuries during manual handling tasks.

Individual in LITE

The individual refers to the person performing the manual handling task. Assess their strength, fitness, and capability to safely handle the load, ensuring they use proper techniques and personal protective equipment to minimize injury risks.

4.1 Human Factors in Manual Handling

Human factors in manual handling include physical capabilities, fitness levels, and individual strength. Each person’s ability to perform tasks safely varies, influenced by health, training, and experience. Assessing these factors helps determine appropriate tasks and reduces injury risks, ensuring individuals are matched to tasks within their physical and mental capabilities for safe handling practices.

4.2 Assessing Individual Capability

Assessing individual capability involves evaluating strength, fitness, and experience to ensure tasks are within safe limits. This includes reviewing health conditions, prior injuries, and training. Employers must match tasks to employees’ abilities, providing necessary support or adjustments to prevent overexertion and injuries, ensuring a safe working environment tailored to individual needs and capabilities for manual handling tasks.

Task in LITE

The task refers to the specific manual handling activity, such as lifting, pushing, or pulling. Understanding task demands is crucial for identifying risks and implementing safe practices.

5.1 Types of Manual Handling Tasks

Manual handling tasks include lifting, lowering, pushing, pulling, carrying, and supporting loads. Each task varies in complexity and risk. For instance, lifting heavy objects from low heights can strain the back, while pushing or pulling requires proper body positioning. Assessing each task type helps in applying appropriate safety measures to minimize injury risks.

5.2 Task-Specific Risks and Mitigation

Task-specific risks vary based on the activity, such as lifting, pushing, or pulling. Mitigation involves training in proper techniques, using handling aids, and conducting risk assessments. Improving workplace layouts and reducing load weights also minimize hazards, ensuring safer manual handling practices tailored to each task’s unique demands.

Environment in LITE

Environmental factors like space, flooring, lighting, and outdoor conditions significantly impact manual handling safety. Proper assessment ensures tasks are performed under safe and hazard-free conditions.

6.1 Environmental Factors Affecting Manual Handling

Environmental factors such as uneven flooring, poor lighting, and confined spaces can significantly impact manual handling safety. These conditions increase the risk of accidents, making it essential to assess and mitigate them. Proper lighting ensures visibility, while clear pathways reduce tripping hazards. Addressing these factors is crucial for creating a safe working environment.

6.2 Mitigating Environmental Risks

Addressing environmental risks involves improving lighting, clearing pathways, and using non-slip surfaces. Ensuring adequate space and installing handrails can reduce hazards; Regular inspections and maintenance of the environment are essential. Additionally, providing appropriate equipment and training staff to navigate challenging conditions effectively minimizes risks, creating a safer workplace for manual handling tasks.

What is TILE in Manual Handling?

TILE stands for Task, Individual, Load, and Environment, a framework for assessing manual handling risks. It helps identify and mitigate hazards systematically to ensure safer operations.

7.1 Breakdown of the TILE Acronym

TILE is an acronym representing four key factors: Task, Individual, Load, and Environment. Each element is crucial for assessing risks in manual handling. The Task examines the activity type, such as lifting or pushing. The Individual considers the person’s capabilities and fitness. The Load evaluates the object’s size and weight. The Environment assesses the surrounding conditions, ensuring safety and reducing injury risks. Proper evaluation of these factors ensures a safer workplace and minimizes potential hazards.

7.2 Importance of TILE Assessment

TILE assessment is crucial for identifying risks in manual handling tasks. By evaluating Task, Individual, Load, and Environment, it ensures a systematic approach to safety. This method helps employers and employees recognize potential hazards, implement controls, and reduce injury risks. A thorough TILE assessment fosters a safer workplace and promotes compliance with health and safety standards, ultimately enhancing overall well-being and productivity.

Task in TILE

Task assessment involves evaluating the specific manual handling activity, such as lifting, pushing, or pulling. It identifies risks associated with the action and ensures safe execution practices.

8.1 Task Analysis for Safe Handling

Task analysis involves breaking down manual handling activities into steps to identify risks. Assessing each movement ensures understanding of the effort required and potential hazards. Evaluating posture, distance, and force helps mitigate risks, promoting efficient and safe handling practices. This systematic approach reduces injury likelihood and enhances overall task efficiency in the workplace environment.

8.2 Identifying Task-Specific Hazards

Identifying task-specific hazards involves evaluating factors like heavy loads, awkward postures, or repetitive actions. Assessing the distance and force required, as well as the task’s complexity, helps pinpoint risks. For example, lifting from low heights or carrying over obstacles can increase injury likelihood. Understanding these risks ensures tailored safety measures, reducing the potential for harm during manual handling activities.

Individual in TILE

Evaluating individual capability ensures tasks are assigned based on a person’s strength, fitness, and skill. This assessment helps prevent overexertion and minimizes injury risks during manual handling activities.

9.1 Individual Assessment for Manual Handling

Individual assessments evaluate a person’s physical capabilities, strength, and fitness for manual handling tasks. This includes reviewing their ability to lift, carry, or move loads safely without causing strain or injury. Factors such as body mechanics, posture, and prior injuries are considered to ensure tasks are within their capacity and to prevent musculoskeletal disorders.

9.2 Role of Personal Protective Equipment

Personal Protective Equipment (PPE) plays a crucial role in manual handling by reducing injury risks. Gloves prevent cuts and slips, back supports stabilize the spine, and protective footwear shields against heavy objects. PPE ensures safety, boosts confidence, and enhances overall task efficiency, making it a vital component of a comprehensive safety strategy in manual handling activities.

Load in TILE

Evaluating load characteristics, such as weight, shape, and surface type, is crucial. Proper handling techniques minimize risks, ensuring safe manual handling practices and reducing injury potential effectively.

10.1 Load Characteristics and Handling Techniques

Load characteristics, including weight, shape, and surface type, significantly impact manual handling safety. Techniques like secure grip, balanced lifting, and proper posture minimize strain. Assessing these factors ensures tasks are executed safely, reducing injury risks and enhancing overall efficiency in the workplace by promoting effective load management strategies.

10.2 Safe Load Handling Practices

Safe load handling practices involve proper planning, using assistive devices, and maintaining control throughout the task. Regular training, ergonomic adjustments, and adherence to weight limits are crucial. Ensuring loads are balanced and pathways are clear minimizes hazards, promoting a safer working environment and reducing the likelihood of manual handling-related injuries.

Environment in TILE

Assessing the environment involves evaluating space, flooring, lighting, and outdoor conditions to ensure safe manual handling, minimizing hazards like uneven surfaces or poor visibility.

11.1 Environmental Assessment for Safety

Environmental assessment involves evaluating physical conditions like flooring, lighting, and space to identify potential hazards. Uneven surfaces, poor visibility, or cramped areas can increase risks. Proper evaluation ensures manual handling tasks are conducted safely, reducing accidents and injuries. Regular checks and adjustments to the environment are crucial for maintaining a safe workplace.

11.2 Implementing Environmental Controls

Implementing environmental controls involves modifying workplace conditions to minimize risks. Ensure proper lighting, secure flooring, and clear pathways to prevent tripping. Regularly inspect and maintain equipment, and optimize workspace layout for safe movement. Adjusting environmental factors can significantly reduce hazards, ensuring a safer environment for manual handling tasks and preventing potential incidents.

Dynamic Risk Assessment in Manual Handling

Dynamic risk assessment involves continuously monitoring and adapting to changing conditions during manual handling tasks. It ensures safety by identifying and mitigating new risks as they arise.

12.1 Definition and Purpose

Dynamic risk assessment in manual handling is a continuous evaluation process. It identifies and mitigates risks as they emerge during tasks. Its purpose is to adapt to changing conditions, ensuring safety remains a priority. This proactive approach complements initial risk assessments like LITE or TILE, providing real-time adjustments to prevent accidents and injuries effectively.

12.2 Conducting Dynamic Risk Assessments

Dynamic risk assessments involve continuously observing and adapting to changing conditions during manual handling tasks. This includes monitoring the environment, adjusting techniques, and communicating with team members. By staying vigilant and proactive, potential hazards can be identified and mitigated in real-time, ensuring tasks are executed safely and efficiently. Regular checks and feedback loops enhance the effectiveness of this approach.

Good Handling Techniques

Good handling techniques involve maintaining a straight back, bending knees, securing the load, and keeping it close to the body. Proper lifting, carrying, and lowering methods reduce injury risks and improve efficiency.

13.1 Proper Lifting Techniques

Proper lifting techniques are essential to minimize injury risks. Stand with feet shoulder-width apart, keep the load close to the body, and maintain a straight back. Bend at the knees, grip the object securely, and lift with leg strength rather than the back. Avoid twisting during lifts and ensure clear pathways. These methods reduce strain and promote safe handling practices, aligning with LITE principles to enhance safety and efficiency.

13.2 Safe Carrying and Lowering Methods

When carrying, maintain a firm grip, keep the load close to your body, and avoid twisting. For lowering, bend at the knees, keep the object near your body, and place it gently. Ensure the area is clear and communicate if assistance is needed. Proper techniques reduce strain and injury risks, aligning with LITE principles to enhance safety and control during manual handling tasks.

Improving Manual Handling in the Workplace

Enhance workplace safety by implementing ergonomic adjustments and optimizing layouts. Train employees on proper techniques and use handling aids to reduce injury risks and improve efficiency.

14.1 Ergonomic Adjustments for Safety

Ergonomic adjustments in the workplace are crucial for minimizing manual handling risks. Ensure workstations and tools are tailored to individual needs, reducing strain. Proper seating, adjustable equipment, and balanced workloads contribute to a safer environment. Regular assessments help identify and address potential ergonomic issues, promoting long-term employee well-being and productivity. These adjustments are vital for preventing musculoskeletal disorders and enhancing overall workplace safety.

14.2 Optimizing Workplace Layout

Optimizing workplace layout is essential for reducing manual handling risks. Ensure efficient workflows, minimal movement, and easy access to materials. Proper storage placement, clear pathways, and adequate lighting reduce hazards. Using handling aids like conveyors or trolleys can minimize strain. Regularly review and adapt the layout to meet changing demands, ensuring a safe and efficient working environment for all employees.

Legal Responsibilities and Compliance

Employers must ensure safe manual handling practices, conduct risk assessments, and provide training. Employees must follow safety protocols and report hazards, adhering to workplace health and safety regulations.

15.1 Employer Responsibilities in Manual Handling

Employers are legally required to ensure manual handling tasks are safe. This includes conducting risk assessments, implementing safety measures, providing proper equipment, training employees, and monitoring practices. Employers must also report incidents and ensure compliance with health and safety regulations to protect workers from injuries. Failure to comply can result in legal consequences and workplace accidents.

15.2 Employee Responsibilities and Awareness

Employees must adhere to manual handling safety guidelines, use proper techniques, and report hazards. They should attend training sessions, follow employer instructions, and utilize provided equipment. Awareness of personal capabilities and task-specific risks is crucial. Employees are responsible for maintaining a safe working environment and contributing to incident prevention. Their active participation ensures compliance with safety protocols and reduces workplace injuries.

Best Practices for Safe Manual Handling

Adopt proper lifting techniques, use handling aids, and conduct regular training. Assess tasks, loads, and environments to minimize risks. Ensure awareness and compliance with safety protocols to prevent injuries.

16.1 Training and Awareness Programs

Effective training programs educate employees on manual handling risks and safe techniques. Regular updates and demonstrations ensure compliance with safety protocols, reducing workplace injuries. Awareness campaigns highlight the importance of proper handling practices, fostering a safety-first culture; Employers should prioritize these programs to maintain a skilled and informed workforce, ensuring tasks are performed safely and efficiently.

16.2 Use of Handling Aids and Equipment

Using handling aids like trolleys, slings, and lifters reduces manual strain and minimizes injury risks. These tools help distribute weight evenly, making tasks safer. Employers should provide appropriate equipment tailored to specific tasks, ensuring compatibility with the load and environment. Regular maintenance and training on equipment use further enhance safety, promoting efficient and injury-free manual handling practices in the workplace.