Paper thickness is a critical factor in printing and design, influencing both functionality and aesthetics. Understanding caliper, GSM, and their applications ensures optimal results for various projects, from business cards to posters.

Understanding Paper Weight and Thickness

Paper weight and thickness are essential properties that determine its suitability for various applications. Weight is measured in grams per square meter (GSM) or pounds (lbs), while thickness is measured in points (pts) or mils. Understanding these metrics helps in selecting the right paper for printing, packaging, or crafting. For example, 80 lb text paper is lighter than 59 lb cover paper due to differences in density and finish. Common ranges include 60-100 GSM for uncoated papers and 150-300 GSM for coated papers. Knowing these specifications ensures optimal print quality, durability, and aesthetic appeal, making it vital for professionals and hobbyists alike to grasp these fundamentals.

Why Paper Thickness Matters in Printing and Design

Paper thickness significantly impacts printing and design outcomes, affecting both functionality and visual appeal. Thicker papers, like 59 lb cover, offer durability and a premium feel, ideal for business cards and posters. Thinner options, such as 80 lb text, are better suited for brochures and letterheads. Proper thickness ensures compatibility with printers, preventing jams and maintaining print quality. Additionally, thickness influences tactile perception, with heavier stocks conveying professionalism and elegance. Choosing the right thickness balances practicality, aesthetics, and cost, making it a crucial consideration for achieving desired results in various creative and commercial projects.

How Paper Thickness is Measured

Paper thickness is measured using calipers or micrometers, expressed in mils (thousandths of an inch) or points, ensuring precise and consistent results for various applications.

Caliper Measurement: Understanding Mil and Points

Caliper measurement is a precise method to determine paper thickness, expressed in mils (thousandths of an inch) or points (1 point = 1/1000 inch). A mil equals one-thousandth of an inch, while a point is equivalent to 0.001 inches. For example, a sheet measuring 0.009 inches thick is 9 points or 9 mils. This system ensures consistency across different paper types and applications. Convertibility between units is straightforward, with 1 mil = 1 point. Understanding these measurements helps in selecting the right paper for printing, packaging, or crafting, ensuring optimal performance and desired results.

Using a Micrometer for Precise Thickness Measurement

A micrometer is a precise tool for measuring paper thickness, offering high accuracy. It measures in thousandths of an inch, ensuring exact readings. To use, place the paper between the micrometer’s anvils and gently tighten. Digital micrometers display readings on a screen, while mechanical ones use a dial. This method is ideal for critical applications where exact thickness matters. Regular calibration ensures accuracy. For best results, measure multiple sheets to account for variations. Using a micrometer helps achieve consistent quality in printing and design projects, making it an essential tool for professionals seeking precise paper thickness measurements.

Converting Between GSM and LBS

Converting GSM (grams per square meter) to LBS (pounds) requires knowing the paper type, as conversion factors vary. Use standardized charts for accurate weight comparisons across different paper categories.

Understanding the Difference Between GSM and LBS

GSM (grams per square meter) measures paper weight, while LBS (pounds) refers to the weight of 500 sheets. GSM is globally consistent, whereas LBS varies by paper type, such as bond or cover. Understanding these differences is crucial for accurate conversions and selecting the right paper for specific applications. Always consult a conversion chart tailored to the paper category to ensure precision in measurements and avoid errors in printing or design projects.

Simplified Conversion Chart for Bond, Text, and Cover Papers

Below is a simplified chart for converting between GSM and LBS for common paper types:

- Bond Paper: 20 lb = 75 gsm, 24 lb = 90 gsm, 28 lb = 105 gsm, 32 lb = 120 gsm

- Text Paper: 50 lb = 74 gsm, 60 lb = 89 gsm, 70 lb = 104 gsm, 80 lb = 118 gsm

- Cover Paper: 65 lb = 176 gsm, 80 lb = 200 gsm, 100 lb = 270 gsm, 120 lb = 300 gsm

This chart provides a quick reference for comparing paper weights, ensuring clarity and accuracy for various printing and design projects.

Paper Weight and Thickness Chart

This chart outlines common paper types, their weights in GSM, and corresponding thickness in micrometers, providing a clear reference for selecting the right paper for your needs.

Common Coated Papers: GSM, Caliper, and Applications

Coated papers offer enhanced print quality and durability. Art paper (80-200 GSM) has a glossy finish, ideal for brochures and posters. Matt coated paper (80-150 GSM) reduces glare, suitable for catalogs. These papers are measured in GSM and caliper, with thickness increasing as GSM rises. Art papers range from 0.065mm (80 GSM) to 0.135mm (157 GSM), while matt coated options vary from 0.075mm (60 GSM) to 0.105mm (128 GSM). They are widely used in packaging, labels, and high-end printing, ensuring vibrant colors and professional finishes. Understanding their specifications helps in selecting the right paper for your project needs.

Uncoated Papers: Offset, Text, and Book Papers

Uncoated papers are versatile and widely used for everyday printing needs. Offset paper, commonly used in commercial printing, ranges from 60 to 80 GSM with thicknesses of 0.075mm to 0.085mm. Text paper, ideal for brochures and marketing materials, typically ranges from 80 to 100 GSM, with a thickness of 0.085mm to 0.105mm. Book paper, designed for publishing, is lighter, ranging from 50 to 80 GSM, with a thickness of 0.055mm to 0.075mm. These papers are cost-effective and suitable for high-volume printing, offering a balance between quality and affordability for various applications.

Specialty Papers: C1S, C2S, and Grey Board

Specialty papers, like C1S (coated one side) and C2S (coated both sides), offer unique finishes for packaging and labeling. C1S papers range from 157gsm to 200gsm with thicknesses of 0.135mm to 0.200mm, ideal for packaging materials. C2S papers, typically 200gsm to 250gsm, are used for premium applications. Grey board, a dense, rigid paperboard, is often 1500gsm to 3000gsm, suitable for heavy-duty uses like signage. These papers provide durability and aesthetic appeal, making them perfect for high-end packaging, displays, and industrial applications where strength and visual impact are essential.

Cover and Cardstock: Thickness and Weight Comparisons

Cover and cardstock papers are thicker and heavier, making them ideal for durable applications. Cover paper typically ranges from 59 lb to 100 lb, with thicknesses of 0.08mm to 0.14mm. Cardstock, heavier and sturdier, ranges from 80 lb to 150 lb, with thicknesses of 0.1mm to 0.2mm. These papers are often used for business cards, postcards, and packaging materials. Their higher caliper and GSM provide rigidity and a premium feel, making them suitable for projects requiring strength and longevity. Understanding their weight and thickness helps in selecting the right stock for applications like signage, folders, and high-end printing projects.

Understanding Paper Types by Weight and Thickness

Paper types are categorized by weight and thickness, with options like text, cover, and cardstock. Each type suits specific uses, from lightweight printing to durable packaging materials.

Text Weight Papers: 80 lb Text and Its Equivalents

Text weight papers, such as 80 lb text, are lightweight and versatile, commonly used for letterheads, brochures, and proposals. They are equivalent to 120 GSM, offering a balance between durability and flexibility. This weight is ideal for everyday printing needs, providing a professional feel without being overly heavy. Text papers are often compared to cover weight papers, which are thicker and more rigid, but 80 lb text remains a popular choice for its affordability and performance. Its moderate thickness ensures smooth printing results, making it suitable for a wide range of applications. Understanding the differences between text and cover weights helps in selecting the right paper for specific projects.

Cover Weight Papers: 59 lb Cover and Its Uses

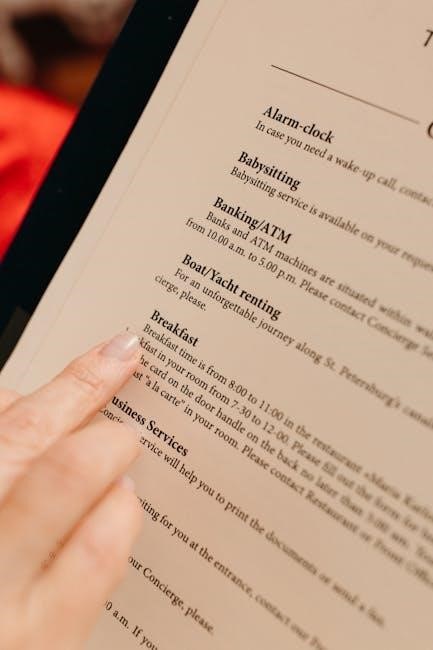

Cover weight papers, such as 59 lb cover, are heavier and more durable than text weight papers, making them ideal for applications requiring rigidity and a premium feel. Equivalent to approximately 167 GSM, 59 lb cover is commonly used for business cards, postcards, and packaging materials. Its thickness, typically around 12 points, ensures it holds up well under handling and provides a professional appearance. This weight is also suitable for brochures, menus, and other materials where a sturdy, high-quality finish is desired. Cover weight papers are a popular choice for projects that require both visual impact and structural integrity, offering excellent printability and durability.

Index and Tag Papers: Thickness and Weight Standards

Index and tag papers are known for their durability and rigidity, making them ideal for applications requiring strength. Typically, 90 lb Index (200 gsm) and 100 lb Tag (250 gsm) are standard weights. Their thickness ranges from 0.006 inches (6 points) for Index to 0.007 inches (7 points) for Tag. These papers are often used for identification cards, loyalty cards, and packaging labels due to their resistance to tearing and bending. Their thickness and weight ensure longevity, making them suitable for heavy-duty use; Index and tag papers strike a balance between flexibility and sturdiness, catering to both functional and aesthetic needs in various industries.

Applications of Different Paper Thicknesses

Paper thickness significantly impacts performance and aesthetics across various applications, from thin printer paper to sturdy cardstock. Common uses include brochures, business cards, posters, packaging materials, and crafting projects.

Printing Applications: Brochures, Business Cards, and Posters

In printing, paper thickness plays a vital role in achieving professional results. Brochures often use 80-100 gsm for a sturdy yet flexible feel, while business cards rely on heavier weights like 59 lb cover for a premium texture. Posters require durable stocks, typically between 150-200 gsm, to withstand outdoor conditions and ensure vibrant color reproduction. The choice of thickness depends on the intended use, with thicker papers offering better durability and a higher perceived value. This balance ensures printed materials are both functional and visually appealing, making paper thickness a key consideration in creating impactful designs.

Packaging Applications: Boxes, Labels, and Folding Cartons

Packaging Applications: Boxes, Labels, and Folding Cartons

Paper thickness is crucial in packaging for durability and protection of contents. Boxes often use thicker, rigid papers like 200-300 gsm to withstand stress, while labels require thinner, yet strong papers around 80-100 gsm for easy application. Folding cartons benefit from medium weights, typically 150-200 gsm, offering both flexibility and structural integrity. The choice of thickness ensures the packaging is both functional and visually appealing, with heavier papers conveying premium quality. This balance is essential for creating packaging that is both protective and attractive, meeting the demands of various industries and consumer expectations for both performance and aesthetics.

Crafting and Art Applications: Card Making and Scrapbooking

In crafting and art, paper thickness significantly impacts the durability and aesthetics of projects. For card making, heavier papers (80-100 gsm) provide stability and a professional feel, while lighter papers (50-70 gsm) are ideal for intricate designs and layering. Scrapbooking benefits from sturdy papers (100-150 gsm) to withstand handling and embellishments. Thicker papers also enhance dimensional effects, making designs more dynamic. The tactile quality of thicker sheets adds depth and texture, crucial for creating visually appealing and long-lasting craft pieces. Choosing the right thickness ensures projects are both functional and artistically satisfying, catering to the creative demands of crafters and artists alike.

Factors Affecting Paper Thickness

Paper thickness varies due to type, grain direction, moisture content, and manufacturing processes. Environmental factors and brand-specific production methods also influence the final caliper of the paper.

Paper Type and Grain Direction

The type of paper significantly impacts its thickness, with coated papers generally being thicker than uncoated ones. Grain direction also plays a role, as paper is more flexible when the grain runs parallel to the longer side. Different manufacturing processes and finishes, such as matte or glossy coatings, further influence the caliper. Specialty papers, like C1S or C2S, often have unique thickness profiles due to their coatings. Understanding these factors helps in selecting the right paper for specific applications, ensuring both functionality and aesthetic appeal. This knowledge is essential for achieving desired results in printing, packaging, or crafting projects. Always consider paper type and grain when planning your design.

Moisture Content and Environmental Factors

Paper thickness is influenced by moisture content and environmental conditions. High humidity can cause paper to absorb moisture, increasing its thickness and weight, while dry conditions may reduce it. This hygroscopic nature means paper expands or contracts depending on its surroundings. Environmental factors like temperature and humidity levels can alter the paper’s caliper, affecting its performance in printing and packaging. Proper storage in controlled environments is essential to maintain consistent thickness and prevent warping or curling. Understanding these factors is crucial for achieving optimal results in various applications, ensuring paper remains stable and performs as expected in different settings. Environmental stability is key to preserving paper quality.

Brand and Manufacturing Variations

Paper thickness can vary between brands due to differences in manufacturing processes and raw materials. Some brands may use higher-quality pulps or tighter production tolerances, resulting in more consistent thickness. Others might prioritize cost-efficiency, leading to slight variations. Additionally, different manufacturing technologies, such as machine calendering or supercalendering, can affect the final thickness and density of the paper. These variations are important to consider when selecting paper for specific applications, as they can impact print quality and performance. Always check specifications from reputable manufacturers to ensure the paper meets your project’s requirements for thickness and weight. Brand reliability plays a significant role in maintaining consistent standards.

How to Choose the Right Paper Thickness

Selecting the right paper thickness involves considering your printer’s capabilities, the desired texture, and budget. Thicker papers offer durability, while thinner options save costs, ensuring optimal results for your needs.

Matching Paper Thickness to Your Printer or Press

Matching paper thickness to your printer or press is essential for achieving optimal print quality and ensuring equipment longevity. Laser printers, inkjet printers, and industrial presses have specific thickness requirements to prevent jams and maintain performance. Typically, standard printers handle paper between 80-100 gsm, while heavier stocks like 150-200 gsm are better suited for commercial presses. Always check your printer’s specifications to confirm acceptable thickness ranges. Using paper that is too thick can damage internal mechanisms, while paper that is too thin may not feed properly. Testing samples or consulting manufacturer guidelines can help ensure compatibility and avoid operational issues.

Considering the Desired Look and Feel

Paper thickness significantly impacts the sensory experience of printed materials, influencing both visual appeal and tactile perception. Thicker papers, such as 100-150 gsm, create a sturdy, premium feel, ideal for business cards or high-end brochures. Thinner papers, like 80 gsm, are lightweight and flexible, suitable for letterheads or mass-produced flyers. The choice of thickness also affects durability; heavier stocks resist bending and tearing, making them perfect for packaging or outdoor use. Ultimately, aligning paper thickness with the intended application ensures a balance between functionality and aesthetics, enhancing the overall user experience and perceived quality of the final product.

Budget Considerations and Cost Efficiency

Choosing the right paper thickness involves balancing budget and quality. Thicker papers, like 100-150 gsm, are more expensive but offer durability and a premium feel, ideal for high-end projects. Thinner options, such as 80 gsm, are cost-effective for bulk printing. Understanding GSM helps optimize costs. For example, 80 gsm is standard for office use, while 300 gsm is better for professional marketing materials. Consulting conversion charts can guide decisions, ensuring you don’t overspend on unnecessary thickness. Matching paper weight to its intended use ensures cost efficiency without compromising quality. This approach helps allocate resources wisely, making projects both budget-friendly and visually appealing.

Measuring Paper Thickness at Home

Measure paper thickness at home using a caliper or by stacking sheets. A caliper provides precise readings, while estimating with a known thickness stack offers a quick guide.

Using a Caliper for Accurate Measurements

A caliper is the most precise tool for measuring paper thickness, providing readings in mils or points. Place the paper on a flat surface, ensure it’s smooth, and close the caliper gently. Digital calipers offer high accuracy, while mechanical ones require careful adjustment. Measure multiple sheets for consistency, as thickness can vary slightly. Always calibrate the tool before use and avoid measuring curled or warped paper. For precise results, use a high-quality caliper designed for thin materials. This method ensures reliable data, essential for printing and design projects where paper thickness is critical. It’s a simple yet effective way to achieve accurate measurements at home or in a professional setting.

DIY Methods for Estimating Paper Thickness

Estimating paper thickness at home can be done without specialized tools. One method involves stacking multiple sheets and measuring the total height with a ruler. Divide the height by the number of sheets to estimate per-sheet thickness. For example, 10 sheets measuring 1/8 inch thick would be approximately 0.0125 inches per sheet. Another method is comparing against known thicknesses, like a standard credit card (0.76 mm). While not highly precise, these techniques provide a practical approximation for casual use. They’re ideal for crafting or small-scale projects where exact measurements aren’t critical, offering a quick and effective way to gauge paper thickness at home.

Troubleshooting Paper Thickness Issues

Inconsistent thickness can cause printing errors or jams. Check for curl or warping, and ensure paper matches your printer’s specifications. Adjust settings or switch stocks if needed.

Dealing with Inconsistent Thickness in Printing

Inconsistent paper thickness can lead to printing issues like jams, uneven ink distribution, or misalignment. Causes include manufacturing variations, moisture absorption, or improper storage. To address this, ensure paper is acclimated to the printing environment. Check for visible curl or warping and use a caliper to measure thickness across sheets. If thickness varies significantly, consider sorting sheets or adjusting printer settings. For severe inconsistencies, consult the paper manufacturer or switch to a more stable stock. Regularly maintaining printing equipment and using high-quality paper can also minimize thickness-related problems, ensuring smoother and more professional print outcomes.

Adjusting for Paper Curl and Warping

Paper curl and warping can disrupt printing and design projects. Causes include environmental humidity, temperature changes, or improper storage. To address this, acclimate paper to the printing environment for 24 hours. For minor curl, use a humidity-controlled space or apply gentle heat with a hairdryer. Severe warping may require professional flattening or replacement. Always store paper in a dry, cool area to prevent issues. If using a printer, ensure settings match the paper type to avoid further distortion. Regularly inspect sheets for curl before use and consider using humectant packs to maintain stable moisture levels. This ensures smooth, professional results every time.

Matching Digital Designs to Physical Paper Thickness

Ensuring digital designs align with physical paper thickness is crucial for achieving the desired aesthetic and functionality. Paper thickness affects how colors appear and textures feel, so selecting the right weight is essential. Use a paper weight chart to match your design’s digital mockup with the appropriate GSM or caliper. Consider the paper’s opacity, rigidity, and finish to maintain visual consistency. For instance, thicker papers like 59 lb cover offer a premium look, while lighter stocks may appear more delicate. Testing prototypes can help bridge the digital-physical gap, ensuring your final product meets expectations and delivers a professional finish.

Understanding paper thickness is crucial for achieving desired results in printing and design. Balancing functionality and aesthetics ensures optimal outcomes. Use conversion charts and calipers for precise measurements, enhancing your projects effectively.

Paper thickness plays a vital role in printing and design, impacting both functionality and aesthetics. Key points include understanding caliper and GSM measurements, converting between units like pounds and grams, and recognizing how thickness varies by paper type. Common applications range from business cards to packaging, with thickness influencing durability and visual appeal. Factors like moisture and grain direction also affect measurements. Using tools such as micrometers ensures accuracy, while conversion charts simplify comparisons. Balancing weight, thickness, and cost is essential for achieving desired results. Proper understanding and measurement of paper thickness enhance project outcomes, ensuring quality and consistency across various uses.

Final Tips for Working with Paper Thickness

When working with paper thickness, always match the weight and caliper to your printer or press specifications to avoid jams or poor print quality. Consider the desired look and feel, as thicker papers often convey durability and professionalism. Budget wisely by balancing cost and quality, ensuring you don’t overspend on unnecessary thickness. Store paper in a dry environment to prevent moisture-related warping; Use a caliper for precise measurements, and refer to conversion charts for GSM to LBS equivalencies. Finally, test samples before large-scale projects to ensure compatibility and achieve the best results for your specific needs.